Turn-key Colorado Fiber Optic Installation

Trace Fiber Services specializes in turn-key fiber installation for backbone and middle mile network applications.

Infrastructure Grade Communications Services

Services for your new and existing communications infrastructure

Fiber network operators need a reliable partner that can handle all phases of network construction and Trace Fiber Services answers the call. Trace brings specialized equipment, crews, and processes to support fiber construction throughout the Mountain West.

Trace Fiber has deep experience in conducting new build, network upgrades, and emergency repair. Our team’s long history of working in crowded right-of-ways and the difficult terrain of the Rocky Mountains will get your network operational sooner.

Trace’s fiber network capabilities include:

-

Fiber network design and engineering services

-

Construction site survey

-

Traffic safety planning

-

Municipal permit & utility locate coordination

-

Directional drilling

-

Trenching, microtrenching, and plowing

-

Handhold installation

-

Fiber jetting and microduct installation

-

Fiber optic cable installation

-

Fiber Splicing

Directional Drilling

Directional drilling (also known as Horizontal Direction Drilling, HDD) is a critical construction capability for communications networks.

Horizontal Directional Drilling

Directional drilling is a trenchless method of installing conduit in right-of-ways that minimizes impact on the surrounding environment. This technology is the gold standard for installing conduit and fiber optic cable in Denver’s crowded utility right of ways. HDDs can drill under existing roads, sidewalks, and other surface features.

Trace Fiber maintains a fleet of modern directional drills and all of the support equipment needed to deploy them to work sites. These drill crews work independently and are capable of installing conduit in urban, suburban, and rural settings. Additionally, Trace’s expert crews have deep experience drilling in austere locations and conductions, such as those found throughout the Rocky Mountains.

Direction Drilling services include:

-

Construction site survey

-

Collaboration with municipal permit offices

-

Work with utility locate teams

-

Potholing

-

Boring

-

Rock boring

-

Duct installation and pulling

-

Replacement and removal of existing utility infrastructure

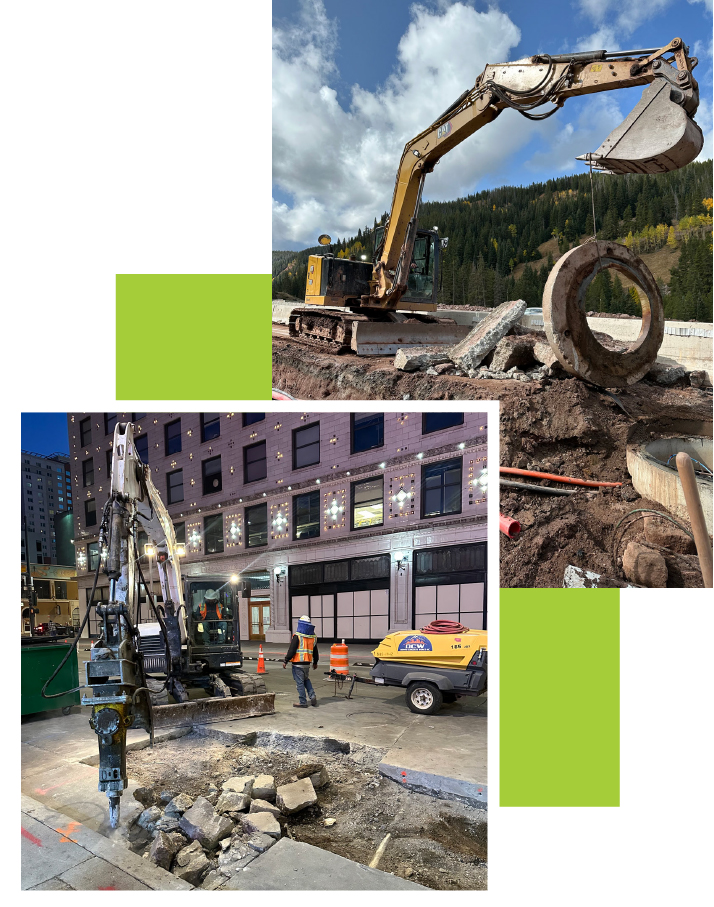

Colorado Light Civil Construction

Civil construction is an essential part of building OSP communications networks and Trace excels at this key skill set

Civil Construction for Communications Networks

While directional drilling and trenching put most of the fiber in the ground, civil construction is necessary to build the required infrastructure for OSP networks. Light civil construction involves digging and installing infrastructure components in the same utility right of ways as the drill teams. This civil construction occurs along the fiber network to ensure access to the ducts and cable.

The Colorado Front Range and Mountain regions require specialized equipment and teams for safe installation of OSP network infrastructure. Trace’s civil construction teams are equipped with mini-excavators, utility vehicles, and other special equipment to remain effective in the varied environments of Colorado. Our civil team’s collaboration with our drill, traffic safety, and fiber splicing teams is essential to delivering projects on schedule and on budget.

Light civil services include:

-

Construction site survey throughout Colorado

-

OSP handhold installation

-

Move or replacement of existing communications network access boxes

-

Pulling or replacing of ducts or fiber

-

Work in environmentally sensitive areas

-

Removal or replacement of concrete

-

Rock or soil backfill

-

Rock or soil haul away

Emergency Communications Infrastructure Repair

Trace Fiber brings specialized capabilities to rapidly restore fiber networks after a breakage or damage.

Emergency Response for Colorado Fiber Damages

When a fiber damage occurs in Colorado, Trace Fiber is your preferred vendor to get your network operational ASAP. With the increasing prevalence of underground OSP fiber networks in Colorado, breakages are becoming more common. When disaster strikes your fiber network, you need a trusted partner with the experience, equipment, and talent to restore connectivity quickly.

OSP emergency response is more difficult than planned construction because time is of the essence and the conditions vary widely. While some contractors bring a single capability (like civil or fiber splicing), Trace Fiber can repair most fiber damages with internal capabilities. Our Colorado emergency response crews are second to none and can bring our turn-key OSP support to your damage.

OSP emergency response capabilities include:

-

Rapid response throughout Colorado Front Range

-

Collaboration with emergency utility locate teams

-

Civil support for removing debris and exposing work site

-

Experience navigating multiple utility damages

-

Fiber splicing in austere conditions

-

Rapid traffic safety planning and execution

Fiber Optic Installation and Splicing

Outside Plant (OSP) fiber networks are the backbone of modern communication networks, and Trace Fiber supports all types of installation and repair

Splicing and Installation of Fiber Optic Cables

Modern fiber OSP networks provide the fastest and most reliable communications systems available today, but they require specialized support for installation and emergency repair. Trace’s fiber optic technicians have the skills and equipment to support new builds, network retrofits, and emergency breakage repairs.

Our team of fiber professionals are positioned throughout the Colorado Front Range to provide support to on-going or emergent projects. Our mobile crews are equipped with the latest splicing technology and can work in austere conditions.

Fiber splicing is the process of joining two fiber optic cables together to establish a clean and effective connection (learn more about fiber splicing). Connecting fiber optic cables is important when establishing a long run of new fiber, adding a new network leg, or repairing a damaged cable. Fiber must be fused in a controlled environment because small deviations or amounts of debris can significantly degrade the fiber’s ability to carry data. Trace Fiber utilizes specializes fiber splicing vans to allow our technicians to splice in clean conditions, even in rural or mountainous environments. Trace also employs modern splicing and diagnostic equipment so issues can be detected early and clean splices are made every time.

Fiber splicing and network capabilities include:

-

Fiber OSP network design and engineering

-

Field fiber splicing and termination

-

OTDR traces

-

Emergency fiber repair

-

Collaboration with OSP network operators to diagnose issues

Rural Communications Trenching and Plowing

Rural fiber network deployments require creative solutions to reduce installation costs and Trace can meet the challenge with trenching and plowing.

Trenching & Plowing for Communications Networks

While directional drilling is the norm for urban and suburban fiber installations, it can be host prohibitive for rural or very rural OSP installation environments. Utilizing a combination of trenching, microtrenching, and plowing can yield faster and cheaper fiber deployments in the right circumstances.

Trace Fiber is experienced and equipped to perform cost effective rural fiber OSP installations with the right technologies. We have a track record of right-of-way trenching and plowing across the Mountain West.

Rural installation techniques include:

-

Trenching

-

Micro-trenching